Precise CNC Spare Parts for Green Production

How precision, sustainability and innovation converge in the overlooked but vital world of CNC spare parts.

At pre-dawn on many factory floors the whine of CNC spindles is a language: tight, steady, and stubbornly consistent. Those sounds arrive only when thousands of tiny engineering choices — down to the surface finish on a bearing race — align. Spare parts are the quiet arbiters of that alignment. They decide whether a day’s production meets spec or becomes a pile of scrap.

Why CNC Spare Parts Are Crucial

Large industrial facilities run on trust: trust that machines will hold geometry, that cycles will repeat, and that product will exit the line within tolerance. That trust is largelyvested in replaceable components — tool holders, spindle bearings, linear guides, coolant nozzles and ball screws. These components are small in profile, huge in consequence.

Well-known industrial actors such as GEA, Siemens, Pentair, ADM, Nestlé and Paktech routinely require spares that integrate mechanically and digitally into automated production lines. They expect parts that arrive ready to perform — not merely to fit.

“When a spindle deviate

s by 0.01 mm, the cost of tolerance failure multiplies across t

housands of parts — from rework bills to customer trust.”

Micro-errors compound: a slight run-out becomes a poor surface finish, which shortens tool life, which drives more frequent stops and unexpected downtime. Spare parts, when engineered and sized correctly, prevent that domino effect.

| Innovation | Description | Benefit | Example Application |

|---|---|---|---|

| Sensor-Embedded Components | Bearings, shafts and holders equipped with vibration and temperature sensors connected to cloud dashboards. | Enables predictive maintenance and real-time monitoring; reduces unplanned downtime. | High-speed spindle systems in aerospace or automotive CNC machining. |

| Additive-Manufactured Spares | 3D printed metal or polymer parts with internal conformal cooling channels or lightweight lattice cores. | Reduced lead times and logistics; improved heat management and dimensional stability. | Custom cooling nozzles and hybrid tool holders for precision milling machines. |

| Hybrid & Composite Designs | Parts combining aluminium, ceramics, or carbon fibre for optimal stiffness-to-weight ratio. | Improves thermal stability and reduces vibration and inertia. | High-precision linear motion assemblies and lightweight spindle housings. |

| Smart Coatings | DLC or nano-ceramic surface layers engineered for lower friction and higher wear resistance. | Extends life of tooling interfaces; reduces lubricant consumption and surface wear. | Tool holders, couplings, and bearing seats operating in continuous duty cycles. |

| Digital Integration | Each spare part includes firmware ID and traceable serials, connecting with MES or ERP systems. | Automatic validation, maintenance history tracking and process transparency. | Smart factories operated by Siemens or GEA with IoT-enabled production lines. |

Precision Manufacturing — From Microns to Millimetres

Precision is measurable. In aerospace or medical devicework, tolerances of ±5 µm are commonplace. Achieving this requires more than accurate CAM programs; it requires components that behave the same under thermal load, dynamic forces and continuous duty.

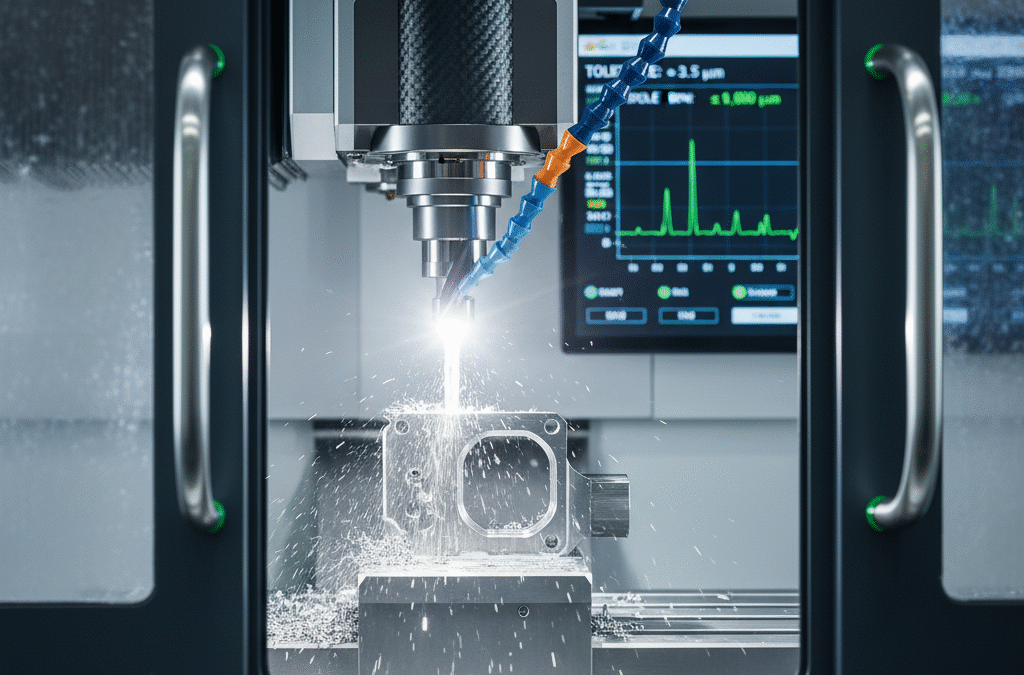

Consider a 12,000 rpm milling spindle cutting titanium. Heat flow, centrifugal forces and micro-vibrations meet at the cutting edge. Bearings must maintain roundness, tool holders must stabilize thermal growth, and ball screws must resist backlash. A single updated spare part — for example, a ceramic hybrid bearing or a DLC-coated tool holder — can reduce run-out, extend tool life and improve first-pass yield.

Engineering levers that matter

- Surface treatments and coatings (DLC, nitriding) that reduce friction and wear.

- Material selection (carbide, ceramics, high-grade steels) that improves fatigue life.

- Precision metrology and traceability so each spare can be matched to machine tolerances.

When spare parts are designed as system elements — not generic replacements — they unlock higher uptime and reduced per-part CO₂ intensity across a product’s lifecycle.

Sustainability in Spare-Part Manufacturing

Spare part sustainability is a layered problem: source material, manufacturing waste, operational energy and end-of-life. Because spares often use exotic alloys and engineered ceramics, the sustainability gains come from smarter design and smarter service models.

Material Efficiency & Waste Reduction

Advanced CAM nesting, multi-axis roughing strategies and near-net-shape forging reduce scrap. When manufacturers optimise toolpaths and heat treatments specifically for a spare part, they save raw material and energy. The gains are measurable: less material removed, fewe

r heat cycles, less rework.

r heat cycles, less rework.

Longevity & the Circular Economy

Designing spares to be refurbishable is a practical sustainability win. Regrinding, partial re-machining and recoating extend life and lower embodied emissions. In many shops, a reconditioned part uses a fraction of the CO₂ embodied in a new one.

Localisation & On-Demand Production

Additive manufacturing and microfactories enable local, on-demand spare production. That cuts lead times, reduces inventory and shrinks the shipping carbon footprint. For slow-moving legacy machines this is a game changer: parts that once took weeks to source can be manufactured in hours.

Numbers that matter:A refurbished spindle bearing may carry 20–70%</ less embodied carbon than a new one. On-demand printed parts can reduce logistics emissions by up to 90% for specific low-volume replacements.

Innovation in the Spare-Part ecosystem

As machines become smarter, spares must join the network. Innovation is pushing spare parts from passive metal to active cyber-physical components.

Sensor-Embedded Spares

Bearings with temperature and vibration sensors, tool holders that report run-out, and couplings that measure torque ripple: these spares emit real-time health data. That telemetry feeds predictive maintenance algorithms and avoids unexpected breakdowns.

Additive Manufacturing & Hybrid Designs

3D printing introduces complex internal geometries — like conformal cooling channels — that reduce thermal distortion and enable new performance envelopes. Hybrid parts (metal skeletons with ceramic liners or carbon-fibre stiffeners) lower inertia and stabilise thermal behaviour.

Digital Integration with Production Lines

Major brands and system integrators now ask that spare parts be digitally native: firmware IDs, compatibility flags, and maintenance histories. That way, a part replacement can be validated and recorded automatically in the MES before the line restarts. This level of integration is increasingly requested by companies such as Pentair, Nestlé, and

others that host complex, fully automated lines.

Case Study — From Spare Part to Sustainable System

Imagine a canned-beverage plant outside Munich. A servo drive shaft begins to drift after roughly 8

,000 hours. Built-in vibration sensors (part of the shaft assembly) flag a rising anomaly. The plant sources a refurbished, re-coated shaft from a local additive microfactory. Swap time: under two hours. Result: downtime reduced, scrap cut by 50%, and energy consumption slightly lower because the servo no longer hunts to maintain position.

Small steps like this — replacing reactive replacement with predictive, and single-use with refurbish — produce measurable reductions in cost and carbon over a year.

| Focus Area | Strategy / Practice | Measured Impact | Industry Example |

|---|---|---|---|

| Material Efficiency | Use near-net-shape forging, adaptive CAM toolpaths and multi-axis roughing to minimise waste. | Up to 20% less raw material consumption per component. | ADM-inspired process optimisation reducing energy use in production lines. |

| Longevity & Circularity | Regrinding, re-coating and re-machining worn parts instead of full replacement. | 50–70% lower embodied carbon per refurbished part. | Spindle re-coating services across GEA and Pentair maintenance networks. |

| Localisation of Production | Adopt micro-factories or additive hubs near end-use facilities. | Reduced shipping emissions by up to 90% for low-volume spare parts. | On-demand manufacturing near beverage facilities of Nestlé and Paktech. |

| Digital Monitoring | Integrate IoT sensors in spares to monitor performance and energy draw. | 5–10% reduction in downtime and maintenance energy per machine cell. | Siemens smart-factory pilot systems in European manufacturing hubs. |

| Lifecycle Documentation | Attach traceable QR or RFID IDs for every spare part’s material source and recycling path. | Improved recycling rate and audit transparency across supply chains. | Adopted by high-compliance sectors like aerospace and advanced CNC machining. |

When suppliers meet those standards, production becomes more resilient and environmentally friendlier — a strategic asset not a recurring cost.