Behind every perfectly sealed beverage bottle or aseptic carton, there’s a silent force at work — precision spare parts. For Sidel, a global leader in packaging technology, spare parts are not just replacements; they’re the DNA that keeps industrial ecosystems alive. Built through advanced CNC machining and sustainable processes, these parts ensure that every rotation, every seal, and every motion counts.

Why Sidel Spare Parts Matter for Modern Manufacturing

In the high-speed world of beverage and food packaging, efficiency is everything. A fraction of a millimeter can decide whether a production line stays profitable or stalls. That’s where Sidel shines — with spare parts designed for exact fit, certified materials, and unmatched reliability.

Comparable systems from Tetra Pak and KRONES also rely on precision-engineered components, but Sidel’s approach integrates digital design verification and real-time feedback to ensure compatibility across generations of machinery. This results in better performance, reduced waste, and fewer unexpected stoppages.

“Precision isn’t a luxury — it’s an ecosystem of trust between machinery and materials.”

How CNC Technology Powers Sidel Spare Parts

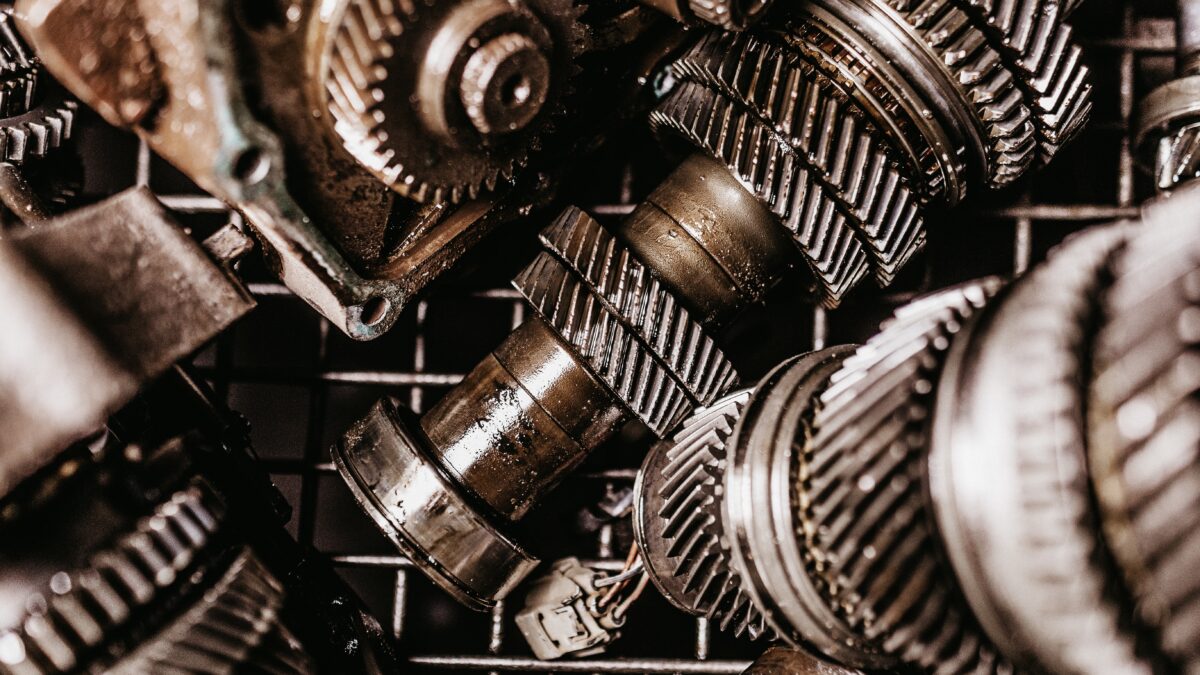

Every Sidel spare part begins as data — a CAD file transformed into a tangible, flawless component using multi-axis CNC machines. Precision down to ±5 microns ensures that the part not only fits perfectly but also enhances the performance of connected systems like P.E. LABELLERS S.P. or Endoline modules used in integrated packaging lines.

During machining, automated quality sensors capture surface roughness, edge consistency, and even micro-temperature deviations. It’s engineering that feels closer to art — and yet, every part must meet industrial demands for durability, traceability, and sustainability.

| Feature | Standard Spare Part | Sidel CNC Spare Part |

|---|---|---|

| Tolerance Accuracy | ±0.1 mm | ±0.005 mm |

| Surface Finish (Ra) | <2.5 µm | <0.8 µm |

| Energy Consumption (production) | High | Optimized, 30% less |

| Material Lifecycle | Single-use | Recyclable / Remanufacturable |

Sustainability Beyond Manufacturing

In the past decade, Sidel has shifted towards a circular manufacturing model — refurbishing components, using recycled alloys, and reducing carbon emissions across supply chains. Every gear, pump, and valve undergoes a full lifecycle assessment, ensuring not only compliance but contribution to sustainability goals.

This mirrors initiatives by industry peers like GUALAPACK and Tetra Pak, both of whom are actively transitioning towards low-carbon materials and smarter logistics systems. Together, these leaders are reshaping the meaning of industrial sustainability.

Business Benefits: Why Genuine Sidel Parts Pay Off

For clients, genuine spare parts are more than a warranty — they’re an investment. Counterfeit or generic parts can cause misalignments, food-safety risks, and long-term damage to expensive equipment. Sidel’s certified spare parts provide:

- Guaranteed Compatibility: 100% fit with OEM equipment.

- Extended Machine Life: Reduces wear and unplanned maintenance.

- Operational Predictability: Full digital tracking and maintenance records.

- Environmental Responsibility: Reusable packaging and remanufactured materials.

| Business Metric | Before OEM Spare Parts | After Sidel Genuine Parts |

|---|---|---|

| Average Downtime (monthly) | 12 hours | 4 hours |

| Energy Use per Unit Produced | 100% | 82% |

| Maintenance Cost per Year | $45,000 | $28,000 |

| Equipment Lifespan | 8 years | 12 years |

Step-by-Step: How to Choose the Right Spare Part Supplier

For businesses managing complex packaging lines, sourcing the right spare part supplier is as important as the machinery itself. Here’s a quick guide:

- 1. Verify OEM Certification: Always check if your supplier is authorized to handle Sidel or Tetra Pak components.

- 2. Ask for CNC Traceability: A transparent CNC record ensures quality and sustainability compliance.

- 3. Compare Sustainability Scores: Look for recycled material usage and closed-loop logistics.

- 4. Evaluate Lead Times: Emergency spare parts should be deliverable in under 48 hours.

- 5. Demand Full Documentation: Include certificates of conformity and environmental compliance reports.

Real Case Story: From Downtime to Delivery

When a beverage manufacturer in Spain faced a sudden filler shaft failure, their Sidel production line halted. Instead of waiting for overseas parts, they partnered with a certified supplier using advanced CNC replication. Within 36 hours, a replacement shaft—machined to Sidel specifications—was installed. Production resumed, saving an estimated €60,000 in potential losses.

The process wasn’t unique. Similar rapid-recovery approaches are now adopted by partners of KRONES and Endoline, who recognize the synergy between precision engineering and sustainability-driven logistics.

The Future of CNC and Sidel Spare Parts

From predictive maintenance to smart supply chains, the next decade will redefine how manufacturers like Sidel and Tetra Pak produce, track, and deliver spare parts. Digital twins will simulate wear, 3D printing will shorten delivery times, and blockchain verification will ensure traceability across continents.

It’s a future where sustainability and performance converge — not as marketing buzzwords, but as business imperatives.

Conclusion

Sidel spare parts represent more than mechanical replacements — they’re precision-engineered commitments to reliability, sustainability, and innovation. Supported by advanced CNC processes and ethical manufacturing, they empower clients to reduce downtime, extend machine life, and minimize environmental impact.